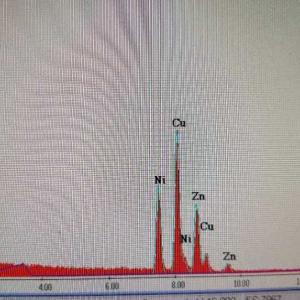

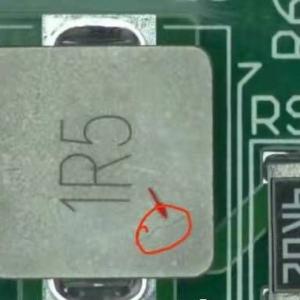

Why does the needle weld off with only copper and nickel, no tin, lead, gold, etc.?

Why does the needle weld off with only copper and nickel, no tin, lead, gold, etc.? The extra zinc may be the alloying element in the gold needle matrix H62 brass (copper-zinc alloy). when the gold coating on the bottom of nickel is very thin, the X-ray tester may be sensitive to the alloying elements in the base metal