RK3588 VDD CPU LIT Power Supply PCB Design

RK3588 VDD_CPU_LIT Power PCB Design

2, VDD_CPU_LIT power supply in the peripheral layer, as much as possible to play the power supply over-hole (more than 9 0.5 * 0.3mm over-hole), to reduce the voltage drop brought about by the layer over-hole; decoupling capacitor GND over-hole with its power supply over-hole to maintain the same number of holes, otherwise it will greatly reduce the role of capacitance.

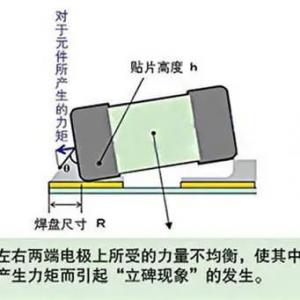

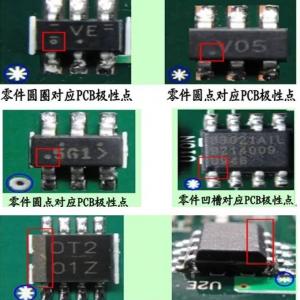

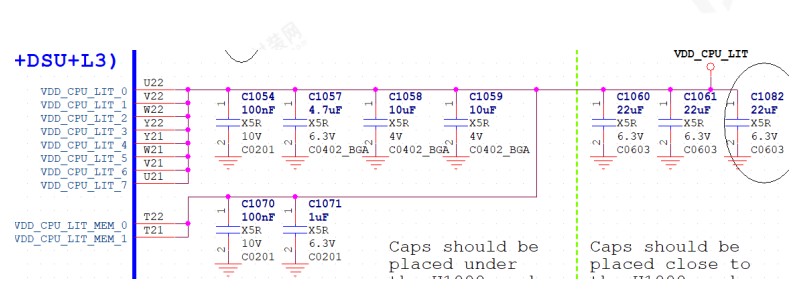

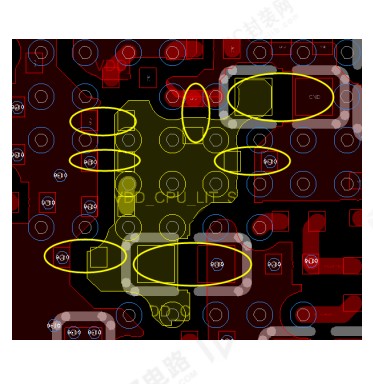

3, as shown in Figure 1, the schematic near the RK3588 VDD_CPU_LIT power supply pin green line within the decoupling capacitors must be placed on the back of the corresponding power supply pin, capacitor GND PAD as close as possible to the chip centre of the GND pin placed, as shown in Figure 2. The rest of the decoupling capacitors are placed as close as possible to the RK3588 chip, and need to be placed in the path of the power split source.

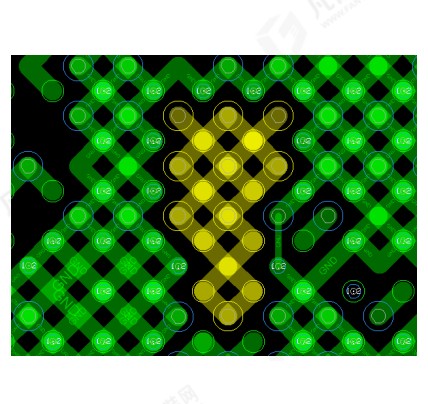

4, RK3588 chip VDD_CPU_LIT power supply pins, each pin near a corresponding hole, and the top walk "well", cross-connections, as shown in Figure 3, it is recommended that the alignment of the line width of 10mil.

Figure 1 VDD_CPU_LIT schematic power supply pin decoupling capacitor

Figure 2 Decoupling capacitor placement on the back of the power supply pin

Figure 3 VDD_CPU_LIT power supply pin "well" chain

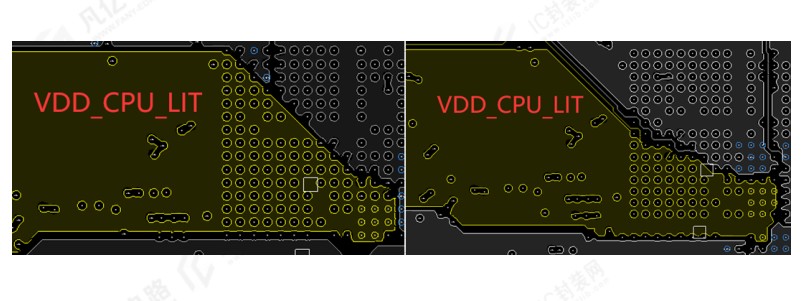

5, VDD_CPU_LIT power supply in the CPU area line width shall not be less than 120mil, the peripheral area width of not less than 300mil, the use of dual-layer power copper cladding to reduce the alignment of the voltage drop (other signals for the layer of holes, please do not arbitrarily placed, must be placed in a regular rule, as far as possible to make room to go to the power supply, but also conducive to the ground layer of copper cladding, as shown in Figure 4).

Figure 4 VDD_CPU_LIT power layer copper cladding situation

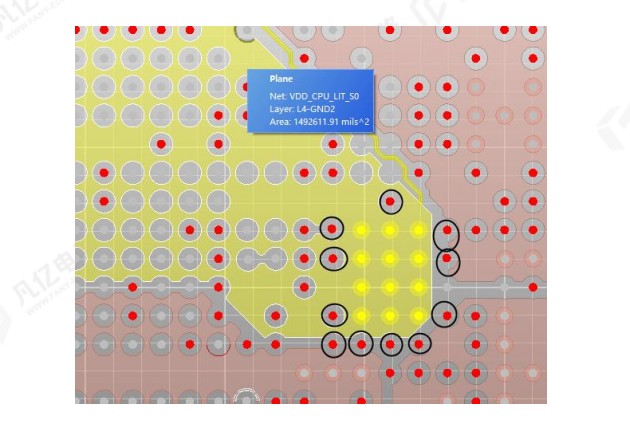

6, power over the hole 40mil range (over the hole centre to over the hole centre spacing) within the number of GND over the hole, it is recommended that ≧ 9. As shown in Figure 5.

Figure 5 LIT power ground over-hole placement map