AOI inspection is essential for PCBA

What is AOI inspection?

Automated Optical Inspection (AOI), an AOI inspection instrument is essential in the SMT placement process of the PCBA industry. It is a new equipment that has only become popular in recent years. It can automatically patrol, automatic alarm, display abnormalities, fully automated. I will give you an introduction to the principle and advantages of AOI inspection in the following.

First, the principle of AOI inspection

Principle.

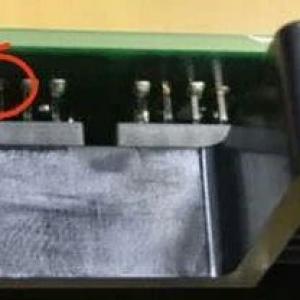

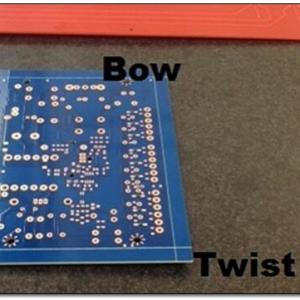

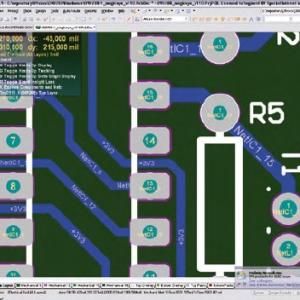

SMT inspection, for example, when the automatic detection, the machine automatically scans the PCB through the camera, collecting images, the test solder joints and the database of qualified parameters for comparison, after image processing, check the PCB on the defect, and through the display or automatic signs to display / mark the defect for repair personnel.Of course, AOI inspection can be used not only for SMT inspection, but also for the following processes.

- 1. After solder paste printing, mainly to check the solder paste printing.

- 2. after SMT placement of components to check whether the placement is correct or not, which can detect errors earlier and reduce costs.

- 3. after chip placement, the inspection system to be able to check the PCB for missing, offset and skewed chips and errors in chip polarity.

- 4. after reflow soldering, at the end of the production line. The inspection system can check the missing, offset and skewed components and component polarity defects.

Second, the advantages of AOI inspection

As some electronic products become smaller and smaller, PCB circuit boards are becoming more and more sophisticated, the difficulty of manual inspection of PCB boards is increasing, the speed of inspection is slower than that of the machine, long time inspection is also easy to produce eye fatigue, resulting in missed inspections. In order to raise the efficiency, AOI can reflect its excellent.The advantages of AOI are as follows.

- 1. saving manpower and reducing labor costs.

- 2. increase production efficiency and raise production capacity.

- 3. unified inspection standards, not due to different lines and differences.

- 4. timely feedback, statistical production problem points.

- 5. collect inspection data, provide process analysis, and strengthen process capability.

- 6. improve the incoming yield rate.

Although AOI inspection has great advantages over manual inspection, but AOI inspection is not foolproof, there will also be technical blind spots, resulting in misjudgment, which then requires manual re-judgment. KEY-PCBA electronics to ensure product quality, at the same time with AOI automatic optical inspection machine manual 100% visual inspection, to improve the rate of good products into the warehouse.

The author of this article, focus on providing PCBA circuit board generation processing, SMT placement, DIP plug-in processing, LED lighting production and electronic products assembly test inspection and other whole process services.

Adhering to the "excellence, quality wins" concept, the main customers belong to the electronic industrial control enterprises, the main management personnel are engaged in PCBA industry for more than 10 years. In the future, we will also take technological innovation as the main line, and constantly update the advanced production equipment to provide high quality and efficient professional services for our customers.