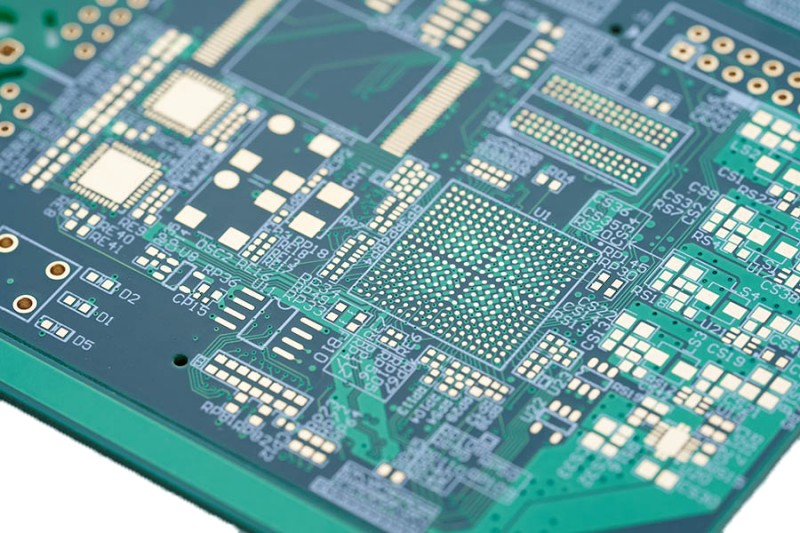

IPC-certified PCB manufacturer

In the field of electronic manufacturing, the quality of PCB (printed circuit board) is directly related to the performance, reliability and service life of electronic products. As a widely recognized specification in the global electronics industry, the IPC (Association Connecting Electronics Industries) standard provides unified and strict guidelines for the design, manufacturing, inspection and other aspects of PCB. For PCB manufacturers, whether they can support the IPC standard has become an important yardstick for measuring their technical strength and product quality. KEY TECHNOLOGY has fully demonstrated its outstanding performance in following the IPC standard with its excellent professional capabilities and strict quality control system. Today, the editor of KEY TECHNOLOGY has specially sorted out the relevant content, hoping that it will help you after reading it!

Production process that strictly follows the IPC standard

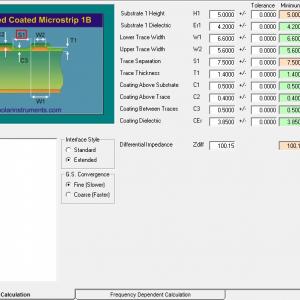

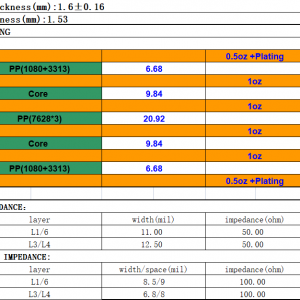

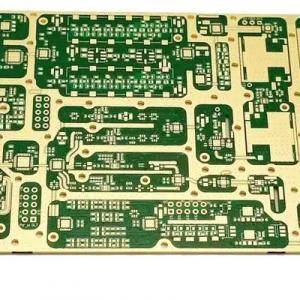

KEY TECHNOLOGY strictly follows the IPC standard throughout the production process, from raw material procurement to finished product shipment. In the raw material procurement link, for materials such as copper clad laminates, copper foils, solder mask inks, etc., they are strictly screened according to IPC-4101 "Specifications for Rigid and Multilayer Printed Board Substrates" to ensure that the electrical properties, mechanical properties, flame retardant properties, etc. of the materials meet high standards. In the PCB manufacturing process, whether it is the lamination process of 1-40 layers of multi-layer boards, or the drilling and electroplating processes of multi-level HDI blind buried boards, IPC-6012 "Qualification and Performance Specifications for Rigid Printed Boards" is followed to accurately control key indicators such as line accuracy, interlayer alignment, and hole wall roughness. For example, when manufacturing high-frequency and high-speed PCB boards for communication equipment, the line layout is optimized according to IPC-2223 "Design Guide for Printed Boards for High-Speed Digital Design" to ensure the stability and high rate of signal transmission.

Advanced equipment helps IPC standards to be implemented

In order to meet the strict requirements of IPC standards for product quality, KEY TECHNOLOGY is equipped with a series of advanced production and testing equipment. In terms of production equipment, advanced CNC drilling machines can achieve high-precision drilling, and the hole diameter tolerance is controlled within a very small range, which meets the IPC requirements for drilling accuracy, and is especially suitable for micro-hole processing of multi-level HDI blind buried boards. In terms of testing equipment, the automatic optical inspection (AOI) equipment conducts a comprehensive scan of the PCB surface according to IPC-A-600 "Acceptance Conditions for Printed Boards", quickly and accurately identifying defects such as short circuits, open circuits, and component placement errors. X-ray testing equipment, based on the IPC-6012 standard, deeply detects the internal interlayer connection quality and solder joint reliability of multilayer boards to ensure that the internal quality of the product meets the requirements. Through these advanced equipment, Shenzhen KEY TECHNOLOGY can effectively implement the IPC standard in every production link to ensure product quality.

Professional team guarantees standard implementation

Shenzhen KEY TECHNOLOGY has an experienced and skilled professional team. Team members have undergone rigorous professional training and have a deep understanding of the IPC standard. Engineers are familiar with the specific requirements of various PCB boards for the IPC standard in different application scenarios, and can formulate personalized production plans according to customer needs. When manufacturing PCB boards for medical devices, the team strictly controls every production detail based on the highest level standard of IPC-A-610 "Acceptability of Electronic Components" to ensure that the products meet the medical industry's extreme requirements for high precision and high reliability. Starting from the Layout design stage, manufacturability and testability are fully considered, and IPC-related design standards are followed; during the production process, operators strictly follow standard procedures, and quality management personnel conduct real-time monitoring and inspection based on IPC standards to ensure that each PCB board can reach a high quality level.

IPC standards help multi-industry applications

With strict compliance with IPC standards, Shenzhen KEY TECHNOLOGY's products are widely used in industrial control equipment, automotive electronics, medical equipment, security equipment, communication equipment and other industries. In the field of automotive electronics, the PCB board of the automotive engine control unit (ECU) needs to operate stably under complex working conditions. The products produced by KEY TECHNOLOGY based on IPC standards have excellent electrical performance and reliability, can withstand harsh environments such as high temperature and vibration, and ensure the stable operation of automotive electronic systems. In the medical equipment industry, PCB boards for key devices such as pacemakers have extremely high requirements for safety and reliability. KEY TECHNOLOGY's products produced in accordance with IPC standards provide reliable guarantees for the precise operation of medical equipment. Shenzhen KEY TECHNOLOGY fully supports IPC standards through strict production processes, advanced equipment, and professional teams, providing customers with high-quality PCB products. The company has IATF16949, ISO13485, ISO9001, ISO45001 and other certifications, serving 50+ countries and regions, 5,000+ global customers, and has the ability to ship 24 hours a day to meet emergency needs. Whether it is a regular order or an emergency project, KEY TECHNOLOGY Electronics uses IPC standards as the cornerstone, provides trustworthy services to many companies in the field of PCB manufacturing, and becomes an important force in promoting the high-quality development of the electronics industry.

The above is all the content shared by KEY TECHNOLOGY. If you have any related needs such as PCB board making, SMT patch, component purchasing, steel mesh processing, three-proof paint spraying, etc., you can leave a message to us KEY TECHNOLOGY and let us help you with one-stop and fast processing!