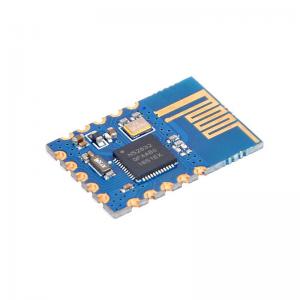

The Core of ADAS: HDI PCBs

HDI boards are the core of ADAS, enabling the close collaboration of sensors and control units that require high-speed processing and real-time response, ensuring the system is both fast and stable.

ADAS has extremely high requirements for signal transmission; any delay can affect safety. HDI boards, through micro-via technology, fine line widths, and high wiring density, achieve high-speed, low-latency signal transmission, ensuring real-time synchronization and processing of data from radar, cameras, and other sensors.

Specific Application Scenarios

* Real-time Decision Control: In scenarios such as automatic emergency braking, HDI boards quickly process data and execute commands, ensuring millisecond-level response.

* Complex System Integration: Integrating ADAS functions (such as adaptive cruise control and lane keeping) into compact modules, HDI technology optimizes space and performance.

Technological Advantages

* Signal Integrity: Micro-via structures shorten signal paths, reducing attenuation and crosstalk.

* Miniaturization and Lightweighting: Meeting the strict requirements of automobiles for space and weight.

* High Reliability: Using high-temperature resistant materials (such as polyimide) to adapt to the automotive environment.

As ADAS develops towards L3+ autonomous driving, HDI boards will evolve towards higher layer counts (such as 12 layers or more), finer lines, and higher frequency materials to support the needs of AI processors and sensors operating at 800MHz and above.