High-speed hair dryer PCBA solution

Regarding the hardware circuits of high-speed hair dryers, from the perspective of the MCU, they can be strictly classified into four types. Currently, these four types of hardware circuits coexist in the market. Recently, some colleagues from other companies visited our company for discussions. What are the advantages and disadvantages of these four hardware solutions, and what are their future development prospects? Below, we will provide a detailed introduction to the characteristics of these four hardware circuits.I. MCU + MOS + Pre-driver

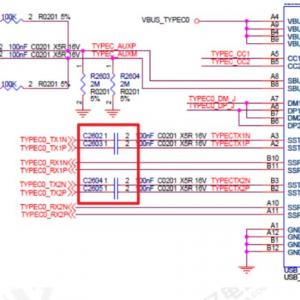

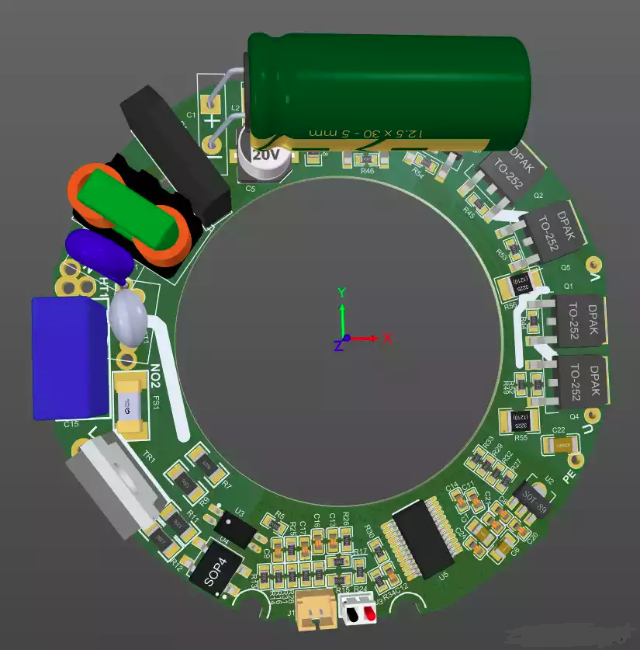

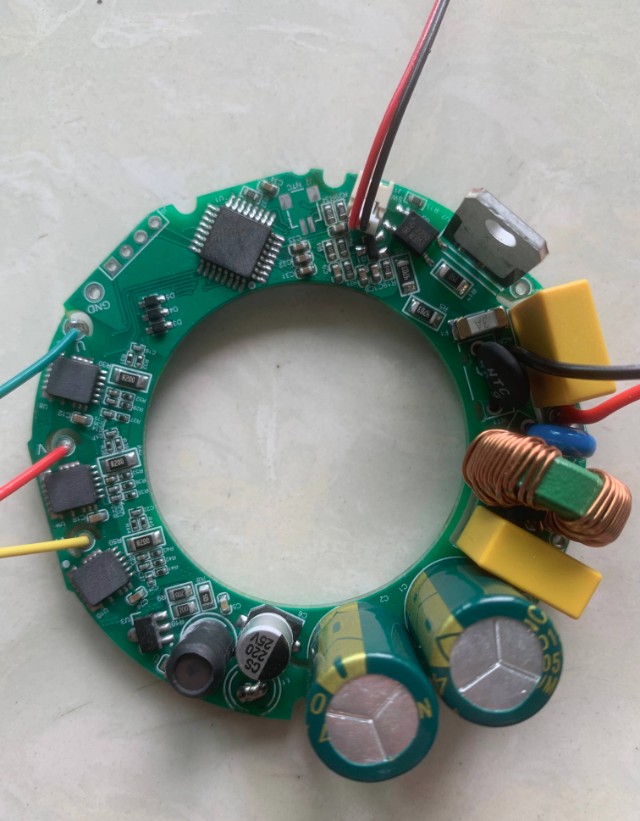

According to the information provided, high-speed brushless hair dryer designs typically use a 32-bit MCU as the main control core, while the brushless motor's switching circuit uses discrete MOSFETs paired with a pre-driver. This design has become the mainstream solution in the current mass-market. The reason this solution is so prevalent is primarily due to its high cost-effectiveness. An MCU with a clock speed of 48MHz or higher is sufficient, and the MOSFETs must have a performance rating of at least 4A. This solution also offers significant flexibility in component selection, making it a cost-effective choice for the high-speed hair dryer market. This is also an inevitable outcome of the competitive landscape in the high-speed hair dryer market.

II. MCU with built-in pre-driver + MOS

Regarding this high-speed fan solution, its advantage lies in its ability to save space, especially when the board area is limited. However, this solution integrates the pre-driver into the MCU through co-packaging, which undoubtedly increases the cost of the MCU. Furthermore, due to the relatively low overall production volume, the reliability of this solution needs further verification.

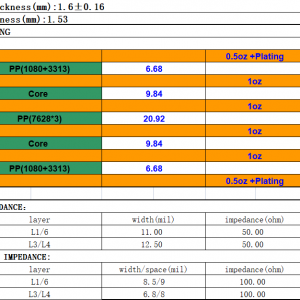

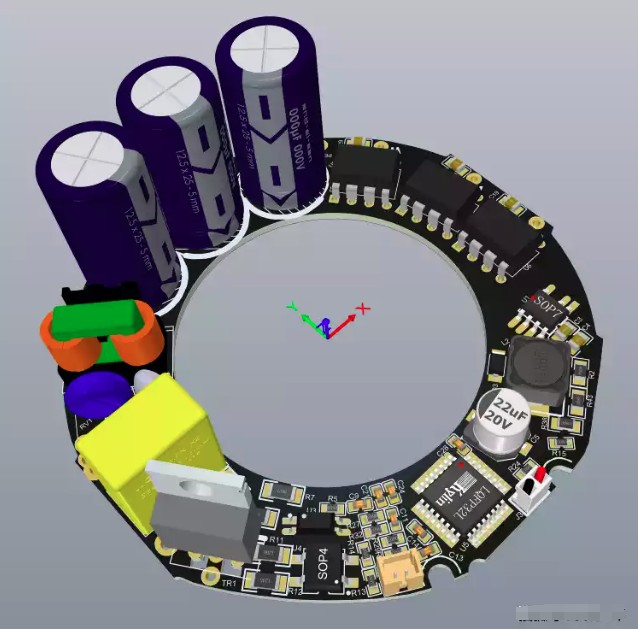

III. MCU + IPM (Integrated Power Module with pre-driver and MOSFETs)

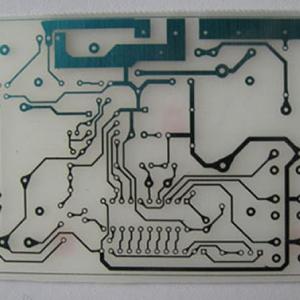

The most significant feature of this circuit is that the MOSFETs and pre-drivers are integrated into a single large IPM package. This design is commonly referred to as a full-bridge driver in the industry. Although the external circuitry is simple, the large size of the IPM makes layout and routing on some circuit boards relatively inconvenient. Currently, this solution is mainly used in circuits of some well-known brands. The advantage of this circuit lies in its simplified MCU peripheral circuitry, due to the integration of six MOSFETs and three pre-drivers within the IPM. Furthermore, the overall consistency of the product is ensured due to the good performance consistency of the entire IPM module.

1. High integration, with built-in 600V pre-driver, fast recovery MOSFETs, bootstrap diodes, and optional temperature sensing function.

2. Optimized packaging design, resulting in significantly lower costs compared to three-phase IPMs, even competitive with discrete pre-drivers and MOSFETs.

3. Excellent heat dissipation capabilities and meets electrical clearance requirements.

4. Compared to three-phase IPMs, it offers flexible PCB layout, adapting to various structures such as ring, strip, and irregular shapes.

5. Compared to discrete pre-drivers and MOSFETs, it has fewer components, lower processing costs, and higher reliability.

6. Product series available, offering options with the same package, 300V/500V voltage rating, and 7A/5A/4A/3A current capabilities.

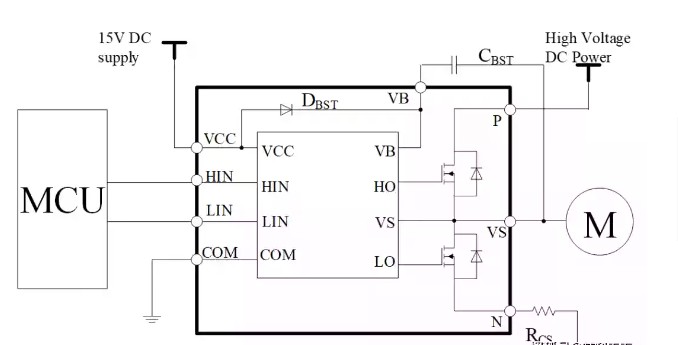

IV. MCU + Half-bridge IPM + Pre-driver

In the field of half-bridge technology, there are currently very few players in the industry. Half-bridge pre-driver products are available in three current ratings: 3A, 5A, and 7A. Prices vary significantly depending on the required operating current. Although several companies have launched such chips, the products still have some issues due to the lack of large-scale application. However, from a price perspective, these half-bridge pre-driver products have an advantage over discrete pre-drivers and MOSFETs.

After comprehensively analyzing the characteristics of the four circuit solutions, it is clear that the MCU + MOS + pre-driver solution offers significant cost optimization advantages and strong market competitiveness.

While the flexibility in choosing MOS and pre-driver components provides a price advantage, the increased number of brands used in combination increases the probability of problems, undoubtedly posing a challenge to product consistency. However, is it truly impossible to guarantee product consistency?

In fact, by selecting high-quality MOS and pre-drivers and ensuring consistent characteristics, the stability of the circuit characteristics can be well-guaranteed.

As for the MCU with built-in pre-driver + MOS or MCU + IPM solutions, their market prospects depend on the suppliers' approach to the market. If IPM module suppliers can meet market demand with reasonable pricing, these solutions still have the potential to gain a foothold in the market. The same applies to the MCU + half-bridge IPM solution.

In summary, the selection and characteristics of high-speed hair dryer design solutions depend on a comprehensive consideration of cost-effectiveness and product structure.

Customers need to weigh various factors to make the decision that best suits their needs.