Description

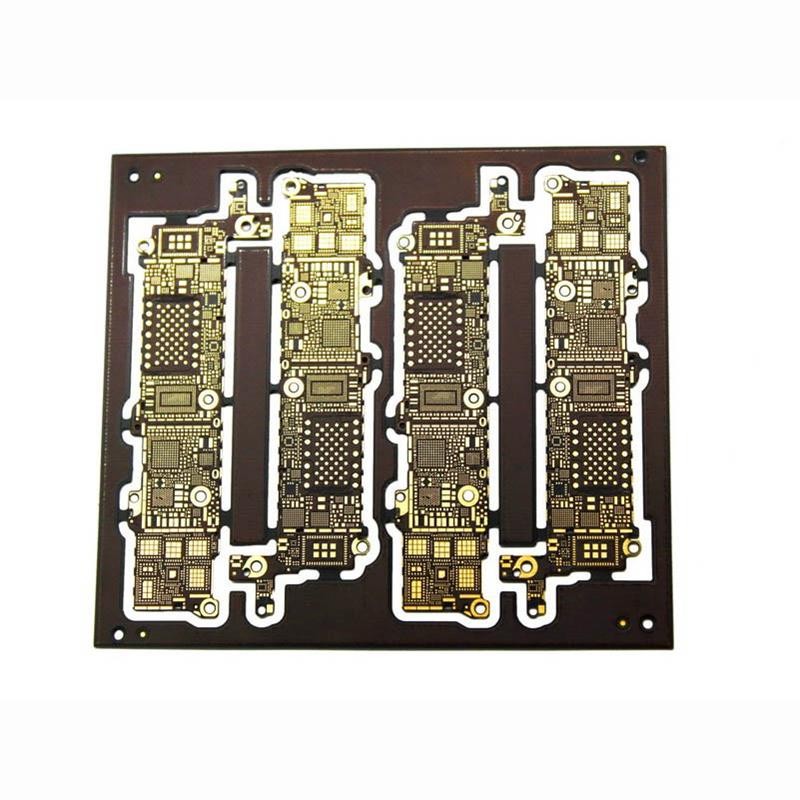

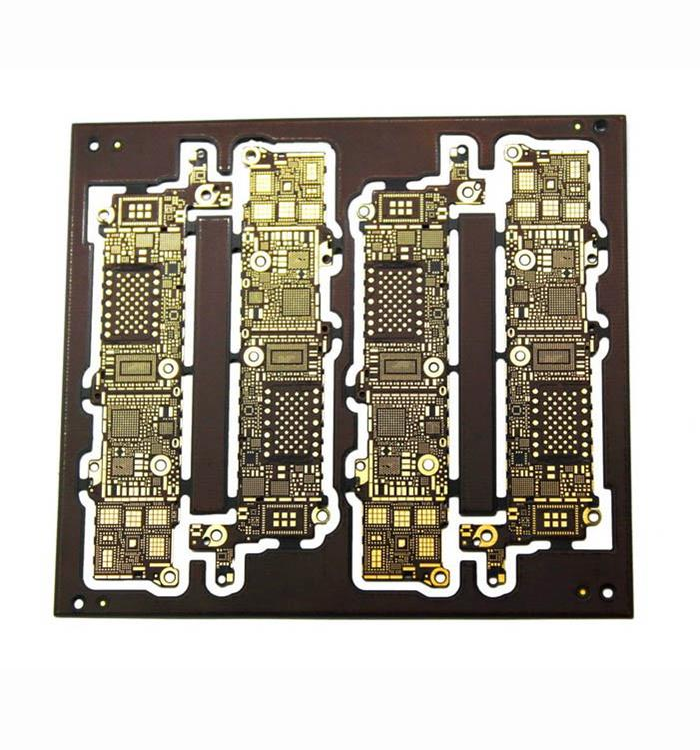

12 layer 2step HDI high-precision buried blind hole HDI PCB

Layers: 12

PCB board thick: 2.0 ± 0.15 mm

Plate used: FR4 ShengYi

Minimum hole diameter: 0.1mm

Surface treatment: ENIG

BGA size: 0.25mm

Minimum trace width/distance: 0.13mm/0.15mm

Blind hole structure: 3R+6F+3R (12 layer 2step HDI)

Process characteristics: HDI blind hole process, high BGA density, small spacing between hole to trace

Application field: high-end digital camera

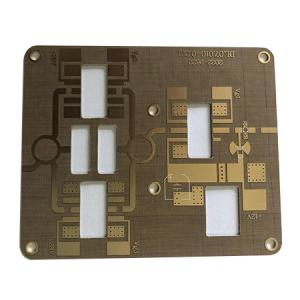

A 2-stage HDI PCB refers to a multilayer printed circuit board (PCB) manufactured using High-Density Interconnect (HDI) technology. It is characterized by the use of micro-blind vias and buried vias for interlayer connection inside the PCB, thereby improving the wiring density and performance of the PCB.

The manufacturing process of a 2-stage HDI PCB generally includes the following steps:

1. Inner layer circuit fabrication: Form copper foil circuit patterns on the inner substrate.

2. Lamination: Bond the inner substrate with the outer substrate together through the lamination process.

3. Drilling: Use laser drilling technology to drill holes on the PCB, including blind vias and buried vias.

4. Copper plating: Copper plating is performed in the drilled holes to increase conductivity.

5. Outer layer circuit fabrication: Form copper foil circuit patterns on the outer layer of the PCB.

6. Surface treatment: Perform surface treatment on the PCB, such as solder mask and silk screen printing.

A 2-stage HDI PCB has higher density, better performance and smaller size compared to traditional PCBs. It is often used in high-end electronic products such as mobile phones, tablet computers, and notebook computers.