Description

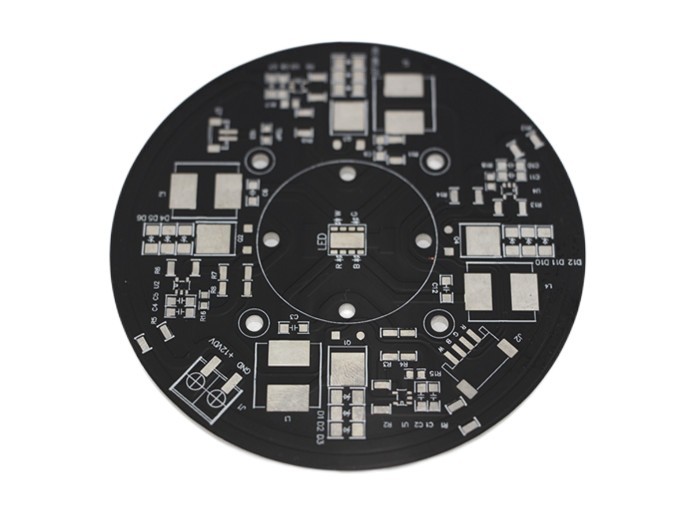

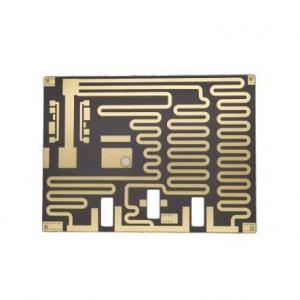

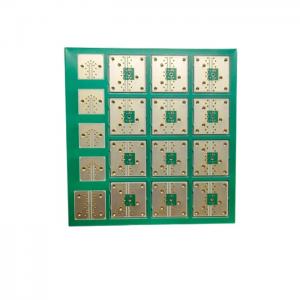

board thick:2.2MM

Pressure resistant:AC1000-2500V

Production Process:Exposure

copper thickness:1OZ

Quality certification:ULE354470/ISO/SGS/IATF16949

Thermal conductivity:2.0w/m.k

soldermask:blacksurface finish:HASL-LF

E-Test

100% Computer open short circuit test

lead time:5-7working days

Here are some ways to improve the heat dissipation performance of aluminum substrate PCB:

- Optimize the design: Reasonably design the layout and traces of the PCB to avoid areas with concentrated heat. A multi-layer board design can be used to increase the heat dissipation channels.

- Use high thermal conductivity materials: Choose substrates with better thermal conductivity, such as aluminum substrate, copper substrate, etc. At the same time, use high thermal conductivity fillers or thermal conductive adhesives to improve the efficiency of heat conduction.

- Increase the heat dissipation area: Add heat sinks, finned heat sinks or radiators on the PCB to increase the heat dissipation area and improve the heat dissipation efficiency.

- Increase the copper foil remaining rate: By reducing the etching amount of the copper foil or using thicker copper foil, increase the remaining rate of the copper foil to improve the thermal conductivity.

- Add thermal conductive holes: Add thermal conductive holes on the PCB to enable the heat to be conducted to the outside more quickly.

- Optimize the heat dissipation structure: Adopt a reasonable heat dissipation structure, such as heat pipes, vapor chambers, etc., to improve the heat dissipation efficiency.

- Control the ambient temperature: Ensure that the aluminum substrate PCB works at an appropriate ambient temperature to avoid the influence of excessive ambient temperature on the heat dissipation effect.