Description

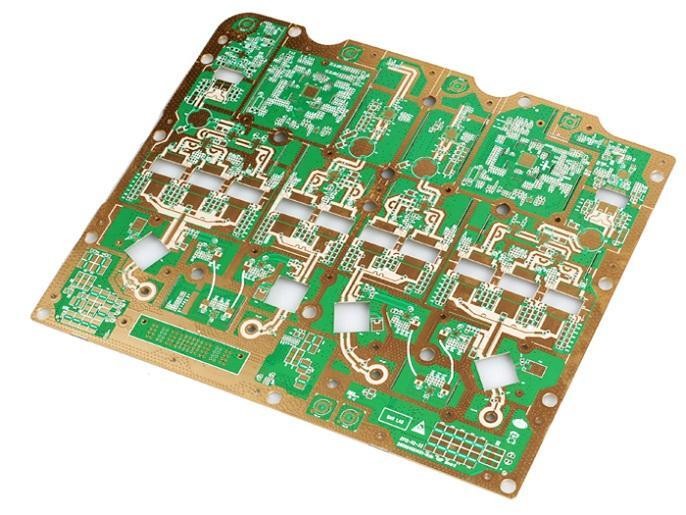

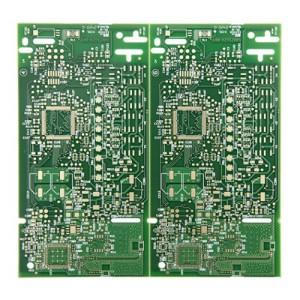

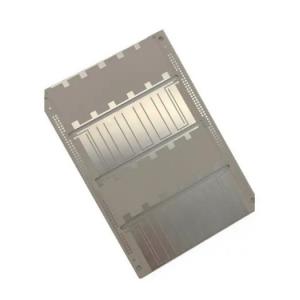

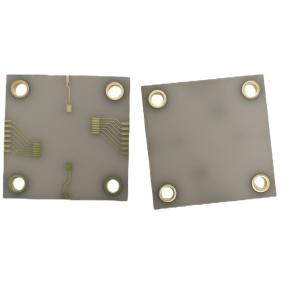

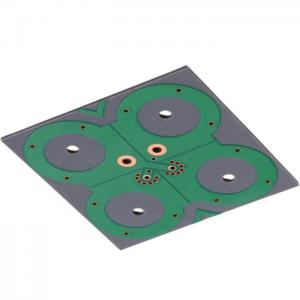

Rogers taconic pcb

Number of floors: 4

Plate thickness: 2.0 ± 0.14mm

Plate used:Taconic+FR4

size:210mm*230mm

Minimum hole diameter: 0.3mm

Surface treatment:immersion gold

Minimum trace width/distance: 0.18mm/0.2mm

Process characteristics: high-frequency materials, Taconic+FR4 Shengyi mixed lamination

Application field: communication

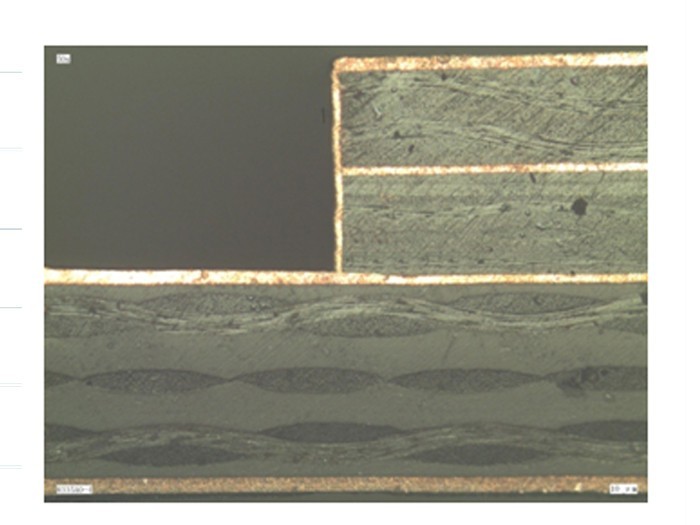

Characteristics of High frequency mixed board: stepped blind slot design

The production process of Taconic PCB includes the following steps:

1. Material Cutting (CUT): Cutting the original copper-clad laminate into boards that can be fabricated on the production line.

2. Inner Dry Film (INNER DRY FILM): Through multiple processes such as film pasting, exposure and development, and inner etching, the inner circuit pattern is transferred to the PCB.

3. Browning: Making the inner copper surface form a microscopic roughness and an organic metal layer to enhance the adhesion between layers.

4. Lamination: Bonding each layer of circuits into a whole with the adhesiveness of the pp sheet.

5. Drilling: Creating through-holes between the layers of the circuit board to achieve the purpose of connecting the layers.

6. Copper Deposition and Plate Electroplating: Including copper deposition and plate electroplating to metallize the holes and thicken the copper layer.

7. Outer Dry Film: Similar to the inner dry film process.

8. Outer Pattern Electroplating and SES: Increasing the copper layer of the holes and circuits to a certain thickness and etching away the useless copper.

9. Solder Resist: Preventing short circuits during soldering by screen printing or coating solder resist ink.

10. Silk-screen Character: Printing the required words, trademarks or component symbols on the board surface.

11. Surface Treatment: Ensuring good solderability or electrical performance.

12. Shaping: Cutting the PCB into the required shape and size.

13. Electrical Test: Checking the electrical performance of the board.

14. Final Inspection, Random Inspection and Packaging: Checking the appearance, size, hole diameter, board thickness, etc. of the board.

The production process of different manufacturers and models of Taconic PCB may vary, and the specific production process may be adjusted according to the actual situation.