The factors and solutions for component misalignment in PCB design.

As electronic devices continue to shrink in size, PCB designers face unprecedented demands for precision. However, the disconnect between ECAD and MCAD processes still leads to costly misalignment problems.

Precision is required at every stage of engineering and manufacturing, yet discrepancies still occur in certain areas. Misalignment of enclosures and connectors often stems from a lack of collaboration between electronic and mechanical design. These problems are frequently exposed during the prototyping phase, and while they may be discovered before production, resolving them is still both expensive and time-consuming.

Recognizing the problem naturally leads to the solution: electronic and mechanical engineers must collaborate on a consistent and clear basis, integrating their design platforms to ensure data transparency.

Before further exploring this integration, let's take a closer look at the specific causes and solutions for component misalignment.

Common causes of design misalignment

Misalignment of enclosures and connectors has been a persistent challenge in hardware development.

These issues are often only noticed when the first prototype is assembled.

While this might seem better than discovering them during early manufacturing, it still consumes valuable engineering time as engineers need to backtrack to the initial layout.

At this stage, the entire supply chain feels the cost pressure due to delays or reordering caused by the extra engineering work.

But why does this happen?

This is partly due to the limited information available to the procurement team.

Typically, procurement is based on the content of Gerber files, which often exclude critical mechanical factors such as:

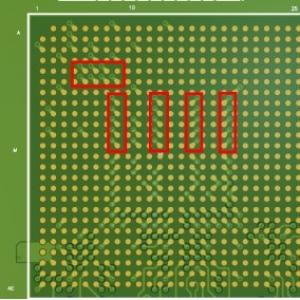

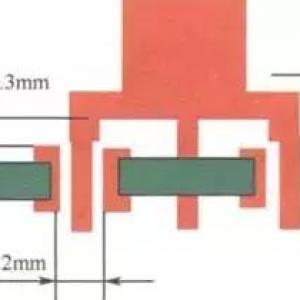

Precise 3D positioning of connectors, buttons, and other mechanical components.

Component height and orientation.

Enclosure or housing specifications.

Mounting hardware, fasteners, or keep-out zones used for assembly.

Tolerance information and other discrepancies in the bill of materials (this issue has significantly decreased in newer, more compact designs).

Assembly instructions and torque specifications.

This highlights the importance of collaboration between electrical and mechanical designers.

Poor collaboration between these design departments stems from: disjointed workflows, outdated file exchange systems, assumptions about connector positioning, and a lack of shared data and reviews.

The disconnected workflow between ECAD and MCAD teams.

The electronics and mechanical teams often operate independently, using different tools, data, and timelines. This disjointed process leads to fragile handoffs, often relying on informal information sharing, thereby introducing human error into the assembly process.

Manual file exchange and version discrepancies

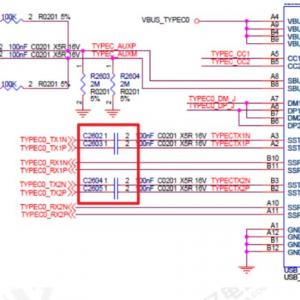

When electronic computer-aided design (ECAD) and mechanical computer-aided design (MCAD) teams lack a shared, consistent, and up-to-date design environment, it becomes difficult for their work to remain consistent, which is reflected in the final prototype. Even minor delays in communication can lead to mismatches between mechanical parts and electronic requirements. This is a common cause of connector misalignment.

Assumptions about Connector Geometry and Mounting Methods

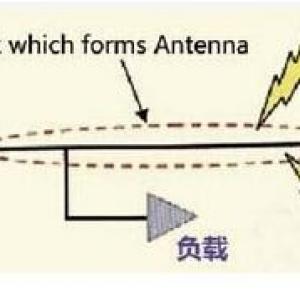

Connectors are not merely schematic symbols, but three-dimensional components with height, orientation, and precise mounting requirements. Misunderstandings about their placement can lead to significant errors throughout the supply chain. Identifying the root cause of misalignment early on can prevent deeper delays later.

With a thorough understanding of the design, the procurement team can source materials during the development phase and urgently needs to understand whether the problem is due to poor fit or incorrect placement.

Lack of shared design rules and references

If the ECAD and MCAD teams do not fully understand the design rules, coordinate origin, or component labeling methods, inconsistencies can easily arise. A connector may appear correctly placed in the electronic blueprint but could have mechanical placement flaws, leading to fit issues or complete mechanical failure.

Irregular and poorly documented reviews

For some enterprises, design reviews conducted in a siloed environment remain the primary cause of dimensional and shape-related issues. Without a collaborative view of the entire electromechanical structure, critical misalignment problems may only be discovered during physical component assembly.

Active Alignment Strategy of PCB Designers

Avoiding misalignment is not just about capturing errors during the design process, but more importantly, coordinating the design team to ensure that such issues occur as little as possible.

With the pursuit of high density in PCB design and the need to meet stricter specifications for connector housing positions, even a small mechanical negligence can have a chain reaction, leading to costly rework or procurement delays.

Proactive methods include improving collaboration between electronic and mechanical teams. In the pursuit of precision, the following strategies can minimize defects in the process that will later manifest as significant production obstacles:

1. Use precise mechanical drawings and 3D models in the PCB and casing design process.

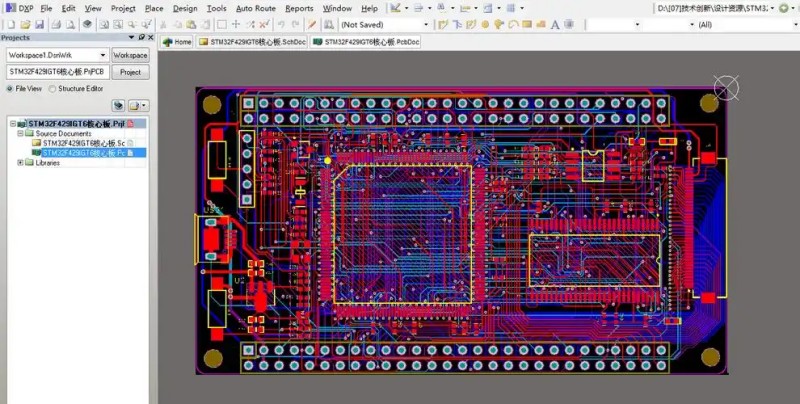

2. Perform 3D inspection in ECAD tools such as Altium's PCB design environment.

3. Add alignment features such as mounting holes and locating pins to guide specific placement on the electronic side (not always applicable for components with smaller tolerance requirements).

4. Use 3D printing or CNC technology to print or produce prototypes of the casing and PCB to verify fit.

5. Promote better workflow between electronic and mechanical engineering teams through integrated design.

MCAD Collaborative Design: Seamless ECAD-MCAD Collaboration

MCAD collaborative design enables real-time, bidirectional collaboration between ECAD and MCAD environments, connecting Altium designs with industry-leading tools such as SolidWorks, PTC Creo, Autodesk Inventor, and Fusion 360. Instead of relying on manual file transfers or outdated models between ECAD and MCAD, teams can instantly share design changes that include complete mechanical context, including 3D geometry and placement data.

Integrating such solutions directly into the tools engineers use helps maintain consistency between the two disciplines, reducing the risk of communication errors and rework. For teams working on increasingly complex or compact designs, this level of precision and collaboration can significantly reduce iteration cycles and accelerate development.

The Value of MCAD Collaborative Design to Teams and Stakeholders

For mechanical engineers, MCAD collaborative design eliminates the guesswork associated with connector and enclosure alignment.

Instead of working from static file exports or outdated models, they can view detailed board-level designs in real time within their native CAD environment.

Electronic designers experience fewer disruptions and faster iteration cycles.

There's no longer a need to wait for feedback or manually regenerate files to communicate intent; instead, there's a single source of truth shared across disciplines.

For all other stakeholders, manufacturers, and all downstream businesses, fewer prototype iterations, shorter development cycles, lower costs, and faster time to market are inherently valuable.

MCAD collaborative design keeps components, teams, goals, and results aligned.

Summary

The industry is being driven by the demand for "rapid market launch", while the complexity and precision of ECAD and MCAD designs continue to increase, making efficiency the core of every precision product. However, the balance between these two often leaves the hidden danger of component misalignment, and the high-speed rhythm may ultimately affect the integrity of the finished product.

Abilities such as MCAD collaborative design enable teams to detect problems early, reduce high rework costs, and enhance collaboration at every stage of development. As devices become increasingly compact and schedules become more tight, bridging the gap between mechanical and electrical has become an inevitable step towards achieving more reliable innovation. When ECAD and MCAD are aligned, the team will accelerate progress, avoid waste, and deliver higher quality products on time according to specifications.