Description

In the electronics manufacturing industry, quality control of PCBA (Printed Circuit Board Assembly) processing is a core element in ensuring product stability and reliability. For companies engaged in the PCBA industry, a deep understanding and mastery of the key elements of PCBA quality control is crucial for improving product quality and enhancing market competitiveness. This article will discuss several key elements of PCBA quality control in detail, aiming to provide a reference for the industry.

I. Component Selection and Procurement

Components are the fundamental building blocks of PCBAs, and their quality directly determines the performance of the final product.

Therefore, component selection and procurement are the primary steps in PCBA quality control.

1. Selecting Reliable Suppliers

Ensuring that components come from reputable and reliable suppliers is fundamental to guaranteeing component quality.

Supplier selection should be based on a comprehensive evaluation of factors such as their historical performance, quality management system, and delivery time.

2. Rigorous Quality Inspection

Components must undergo rigorous quality inspection before warehousing, including visual inspection and electrical performance testing, to ensure that components are undamaged, defect-free, and meet relevant standards and design requirements.

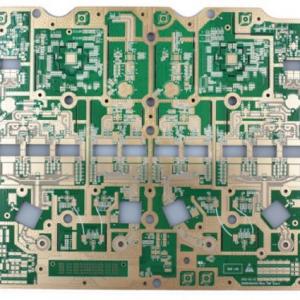

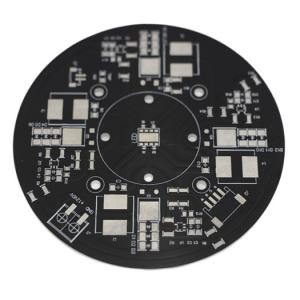

II. PCB Board Selection

As the carrier of the circuit board, the quality of the PCB board is equally important.

Selecting a suitable PCB board is crucial for improving the electrical performance, mechanical strength, and heat resistance of the circuit board.

1. High-Quality PCB Substrate

Selecting a PCB substrate with high thermal stability and low warpage can reduce deformation and stress during processing, improving the stability and reliability of the circuit board.

2.Necessary Inspections Necessary inspections should be performed on the PCB board, such as thickness, flatness, and solder mask quality, to ensure that the board meets design requirements and avoid processing defects caused by board quality issues.

The process flow in PCBA manufacturing directly impacts product quality and performance.

Establishing a comprehensive process flow control system is crucial for ensuring product quality.

1. Standardized Operation

Standardize the process flow, ensuring clear specifications and standards for each operation step to reduce errors and defects caused by human factors.

2. Equipment Maintenance

Regularly inspect and maintain equipment to ensure its good condition and stability.

Train equipment operators to improve their operating skills and awareness, ensuring safe and stable equipment operation.

3. Precise Parameter Control

Determine appropriate process parameters based on product design requirements and implement precise control.

Adjust parameters promptly through real-time monitoring and feedback to ensure product consistency and stability.

IV. Soldering Quality Control

Soldering is a critical step in PCBA manufacturing, and its quality directly affects the product's electrical performance and reliability.

1. Appropriate Soldering Process

Use appropriate soldering processes and parameters to ensure soldering quality.

For example, use RoHS-compliant lead-free solder to ensure soldering quality and meet environmental requirements.

2. Soldering Quality Inspection

Strict soldering quality inspection is performed on the soldered PCB boards, including checks on solder joint fullness and weld strength, to ensure the soldering quality meets design requirements.

V. Testing Technology

Advanced testing technologies are introduced to detect and resolve problems early, preventing defective products from entering the market.

1. AOI Technology

AOI (Automated Optical Inspection) technology uses high-speed cameras and image processing software to quickly and accurately identify soldering defects and misaligned components, improving inspection efficiency.

2. X-Ray Technology

X-Ray technology can inspect the internal soldering quality of complex components such as multilayer boards and BGAs, discovering internal defects that are difficult to detect using traditional inspection methods, ensuring product reliability.

3. ICT Testing

ICT (In-Circuit Testing) uses test probes to contact test points on the circuit board to test the electrical performance of the circuit. It can detect short circuits, open circuits, and component failures on the circuit board, ensuring that the circuit functions normally.

VI. Quality Management System

Establishing a sound quality management system is the foundation for ensuring the quality of PCBA processing. KEY TECHNOLOGY safeguard your PCBA products. Inquiry email: sales@key-pcba.com

1. ISO Certification

Certification with ISO 9001 and other quality management systems ensures that the company has a quality management system that meets international standards, improving the overall quality control level.

2. Total Quality Management

Implementing Total Quality Management (TQM) through total participation, continuous improvement, and customer orientation enhances product quality.

By using statistical methods such as statistical process control (SPC), key parameters in the production process can be monitored and controlled to ensure process stability and product consistency.

VII. Employee Training

The skills and qualities of employees directly impact the quality of PCBA processing.

Continuous training and skills enhancement ensure employees possess the necessary knowledge and skills.

1. New Employee Training

Provide systematic onboarding training for new employees to ensure they understand the basic PCBA processing procedures and quality requirements.

2. Skills Enhancement

Regularly organize skills training and assessments to improve employees' professional skills and operational levels. Encourage employees to provide suggestions for improvement, stimulating their enthusiasm and creativity.

Conclusion

PCBA quality control is a systematic project involving multiple aspects such as component selection and procurement, PCB board selection, process flow control, soldering quality control, testing technology, quality management systems, and employee training.

Through systematic and comprehensive quality control measures, PCBA processing quality can be significantly improved, providing customers with more reliable and stable products and enhancing market competitiveness. As PCBA experts, we should continuously learn and explore, constantly improving our professional qualities and skills to contribute to the development of the electronics manufacturing industry.