Description

In the electronics manufacturing industry, the delivery time of PCBAs (Printed Circuit Board Assemblies) is crucial for customers' project schedules and product launch plans.

Understanding the standard delivery times of PCBA manufacturers, whether these times can be shortened, and the underlying influencing factors helps customers make informed decisions during the project planning phase and allows PCBA manufacturers to optimize their production operations. So, how long does it take to purchase PCBAs from China? Let's take a closer look.Standard Delivery Times of PCBA Manufacturers

The PCBA production process encompasses multiple stages, from board fabrication to electronic component procurement, SMT assembly, component assembly, and final testing and packaging. Each stage requires a certain amount of time, which collectively determines the standard delivery time.

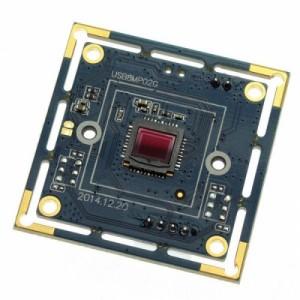

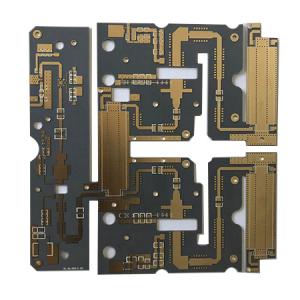

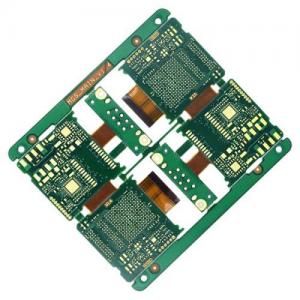

Small to Medium Batch Orders: For small to medium batch PCBA orders with moderate process complexity, the PCB fabrication stage, using standard FR-4 board material, takes approximately 5-7 working days for double-layer boards and 7-10 working days for four-layer or higher multilayer boards. Take about 1 month for rigid-flex PCB. HDI board manufacture time usually depends on how complicated board is.

Component procurement is carried out simultaneously. It's worth noting that many components need to be imported, which typically takes more than 2 weeks. Afterwards, the SMT placement and assembly stages generally take 1-2 weeks, depending on the quantity of components and the complexity of the placement. This process also includes time for raw material inspection, quality control during production, and communication regarding any difficulties. This requires active cooperation with the factory to avoid delays. Under normal circumstances, the total completion time for ordinary PCBA is 3-4 weeks, with air freight via DHL or FedEx taking approximately one week. Therefore, the time from placing the order with the PCBA factory to receiving the package is approximately 4-5 weeks.

Large-volume orders: When the order quantity is large, due to the expanded production scale, more production equipment investment, personnel allocation, and quality control work are involved, and the standard delivery time will be correspondingly extended, usually to 6 weeks or even longer. For example, if a large electronic equipment manufacturer places an order for 100,000 PCBAs with a PCBA manufacturer, the manufacturer needs to coordinate more production resources, including increasing the operating time of the SMT production line, allocating more workers, and arranging a more intensive quality inspection process, all of which will lead to a longer delivery time.

Can Delivery Time Be Shortened?

Theoretically and practically, it is possible for PCBA manufacturers to shorten delivery times, but this requires comprehensive consideration of multiple factors and the implementation of corresponding measures.

Factors Affecting Delivery Time Shortening

Order Characteristics

Order Quantity: When order quantities are small, production arrangements are relatively flexible, allowing manufacturers to complete production tasks more quickly, increasing the likelihood of shorter delivery times.

However, large-scale orders require significant production time and resource allocation, limiting the extent of delivery time reduction even with expedited measures.

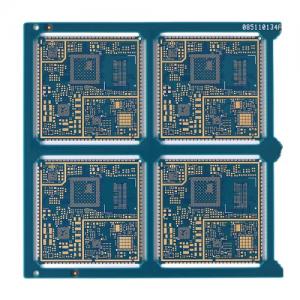

Product Complexity: Simple PCBA products, such as those with only basic resistors, capacitors, chips, and other conventional components, and fewer circuit board layers, have simpler production processes and shorter delivery times.

Conversely, for multi-layer high-density circuit boards and PCBAs containing complex packages such as BGA (Ball Grid Array), the production process is complex, quality inspection is difficult, and shorter delivery times are challenging.

Raw Material Supply

Material Availability: If the required electronic components do not require imports and the PCB board process is simple, manufacturers can quickly procure and put them into production, providing a foundation for shorter delivery times.

However, if certain key components need to be imported or are even out of stock in the market, or if custom-made PCB boards are required, the procurement cycle will be extended, thus affecting the overall delivery time. For some high-end chips, due to global supply shortages, the procurement cycle can last for months, severely restricting the reduction of delivery time.

Material Inspection: Strict quality inspection of raw materials is a crucial step in ensuring PCBA quality, but the inspection process also takes time.

If the inspection process is cumbersome, or if quality problems are found in the raw materials requiring returns or exchanges, the delivery time will be extended. Optimizing the inspection process and adopting more efficient inspection equipment and methods can reduce inspection time while ensuring quality, creating conditions for shortening the delivery time.

Manufacturer's Own Capabilities

Production Equipment and Capacity: KEY TECHNOLOGY as a PCBA manufacturer with advanced and efficient production equipment, has higher production efficiency and larger capacity, giving it an advantage in facing the demand for shorter delivery times.

High-precision, high-speed pick-and-place machines can complete component placement tasks in a shorter time; highly automated production lines can reduce manual operation time and error rates. Furthermore, the manufacturer's production capacity is also crucial. If a manufacturer is simultaneously handling multiple large orders and its capacity is saturated, even with the desire to shorten delivery times, it will be difficult to achieve this.

Production Management Level: A scientific and reasonable production management system can optimize the production process and reduce delays and waiting times in the production process.

Through lean production management methods, production plans can be rationally arranged to reduce inventory backlog and improve production efficiency. Good production management also includes effective personnel scheduling to ensure that there are sufficient personnel working efficiently at each production stage, thereby helping to shorten delivery times.

Technical Team Strength: An experienced technical team can quickly resolve technical problems that arise during production.

In the SMT placement process, issues such as component misalignment and cold solder joints may occur. The technical team can analyze the causes in a timely manner and take effective measures to avoid production stoppages due to technical failures, providing technical support for shortening delivery times.